2026 Best Wire Mesh Weaving Machine Reviews and Benefits?

When it comes to manufacturing, efficiency is key. The right tools can make all the difference. One essential tool for many industries is the wire mesh weaving machine. This machine plays a crucial role in creating wire mesh products used in construction, agriculture, and more. Its versatility allows it to adapt to various requirements.

However, not all wire mesh weaving machines are created equal. With so many options on the market, it can be challenging to choose the best one. In 2026, understanding the features and benefits of these machines is vital for informed decision-making. Many users overlook key aspects, leading to unsatisfactory purchases.

Evaluating the right wire mesh weaving machine means considering material types, weaving patterns, and production capacity. Each detail matters. Investing time in research may prevent common pitfalls. Reflecting on personal needs can lead to better results. This guide will explore reviews and the benefits of top machines to aid your selection.

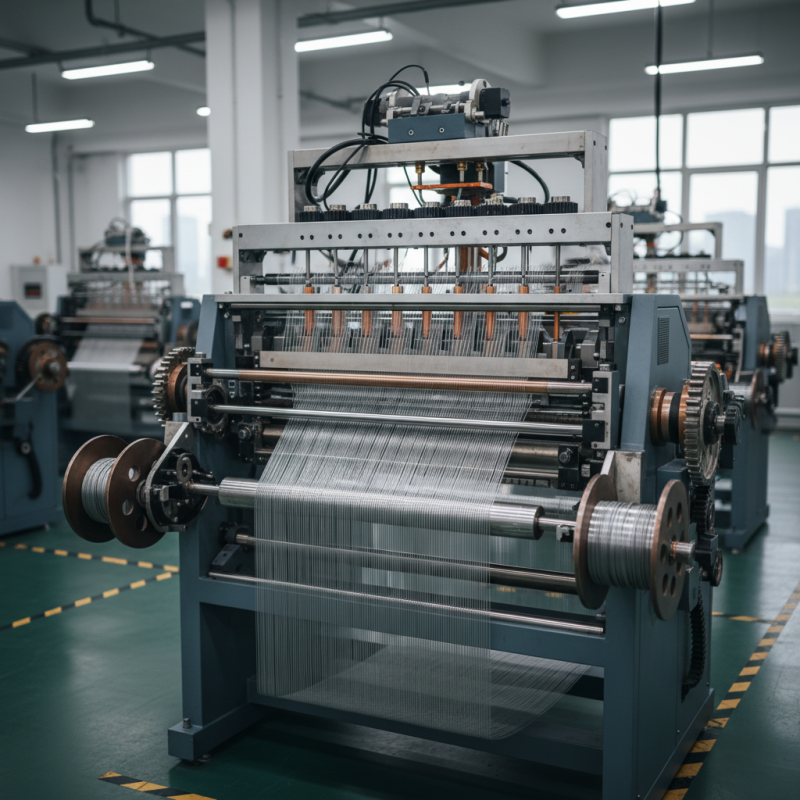

Overview of Wire Mesh Weaving Machines

Wire mesh weaving machines play a crucial role in various industries. They are primarily designed to produce a diverse range of wire mesh products. These products come in different sizes and types, catering to numerous applications. The machines are capable of weaving metal or synthetic wires into intricate patterns. This capability allows for customization based on specific industry needs.

The operation of these machines is not without its challenges. For instance, a malfunction can result in production delays. Regular maintenance is essential but often overlooked. Some operators may find the setup process complex, especially for beginners. Quality control is another area needing attention. Inconsistent mesh quality can lead to product waste and increased costs.

Investing in quality wire mesh weaving machines is beneficial. They can enhance productivity and lower operational costs. However, understanding the machine's intricacies is critical for maximizing performance. Continuous learning and adaptation are key to overcoming the challenges that arise in this industry.

2026 Best Wire Mesh Weaving Machine Performance Comparison

Key Features to Consider When Choosing a Weaving Machine

When choosing a wire mesh weaving machine, several key features matter. Durability is crucial. A sturdy machine lasts longer, even with heavy usage. Look for high-quality materials in the design. This not only ensures longevity but also enhances performance.

Ease of operation is another aspect to consider. A user-friendly interface can save time and reduce frustration. Simple controls allow for quick setup and adjustments. This is critical in a busy production environment. Maintenance features also matter. Machines that require minimal upkeep are often more efficient. Regular maintenance can prevent costly downtimes.

**Tip:** Always evaluate the machine’s capacity. It should meet your production needs. Overbuying can lead to wasted resources. Underbuying can hinder your workflow. Balance is essential.

Consider the machine’s speed as well. A faster machine improves productivity. Yet, it might come with trade-offs in quality. Sometimes, it’s better to choose quality over speed. Reflect on your specific needs. Choosing the right machine involves careful thought and consideration.

Top-Rated Wire Mesh Weaving Machines of 2026

In 2026, the wire mesh weaving machine market continues to evolve. Professionals need machines that balance efficiency and quality. The latest reports indicate a growing demand for advanced technologies. These machines enhance production rates by up to 30%, significantly reducing downtime. Operators can weave different mesh sizes quickly, making them versatile for various applications.

Market analysis shows that precision remains a crucial factor. Many machines struggle to maintain quality at high speeds. Despite technological advancements, some still produce inconsistent results. It's vital for manufacturers to invest in better calibration features. This can ensure better product quality, preventing costly errors. Operator training is also a key area needing attention. Skilled workers can optimize machine performance and reduce waste.

The top-rated machines of 2026 include advanced safety features. However, not all machines prioritize operator safety. A lack of protective measures can lead to serious accidents. Industry reports suggest that this is a critical area for improvement. Investing in machines with robust safety protocols can mitigate risks. Companies must also focus on long-term maintenance plans to enhance durability and reliability in their weaving machines.

Benefits of Using Modern Wire Mesh Weaving Technologies

Modern wire mesh weaving technologies offer numerous advantages for production. These advancements streamline the manufacturing process and improve efficiency. A well-designed machine can reduce labor costs and increase output. Integrating automation features leads to higher precision and consistency in product quality.

Tip: Regular maintenance of your weaving machine is crucial. It helps in preventing unexpected downtimes. Pay attention to minor issues to avoid more significant problems later.

Additionally, modern technologies provide versatility. Manufacturers can quickly adapt their machines to produce various mesh sizes and types. This flexibility meets changing market demands. However, not all machines are user-friendly, which can lead to mistakes in operation. It's essential to invest time in proper training.

Tip: Consider using simulation software for training operators. This method can provide a risk-free environment for learning.

Moreover, the adoption of eco-friendly materials in weaving machines decreases the environmental impact. Some machines can even recycle old materials. While these innovations are promising, the initial investment can be substantial. It's vital to analyze long-term benefits before committing.

Maintenance Tips for Prolonging the Life of Weaving Machines

Maintaining a wire mesh weaving machine is crucial for longevity. Regular cleaning keeps dust and debris from affecting performance. A simple wipe down can make a big difference. Inspecting moving parts is vital, too. Lubricating these areas reduces wear and tear over time. Remember, a little maintenance goes a long way.

Another key aspect is monitoring tension settings. Incorrect tension can lead to uneven weaving. It's essential to check these settings frequently. Machine parts can loosen over time. Tightening them regularly can prevent major issues. Additionally, scheduling professional inspections can be beneficial. Experts can identify potential problems before they escalate.

Even with good maintenance, machines may face unexpected challenges. Learning from these moments is important. Sometimes, simply adjusting your approach can lead to improvements. Every machine has its quirks. Understanding these can enhance your weaving outcome significantly. Embrace the learning process; it’s part of the journey.